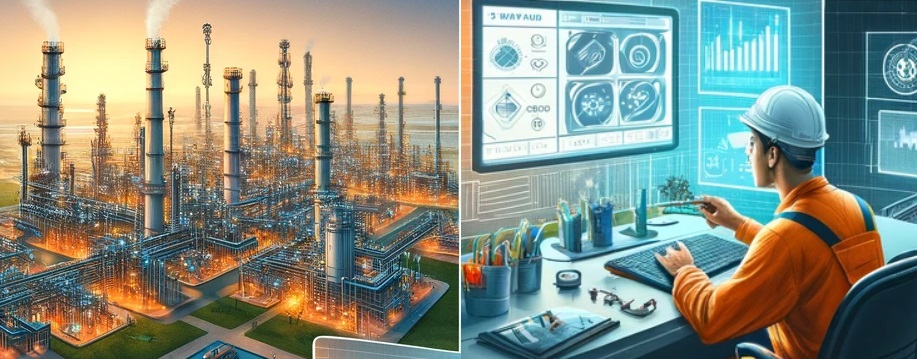

The integration of the Internet of Things (IoT) in industrial settings is revolutionizing the way refineries operate, particularly in the optimization and management of fired heaters. This article explores the potential impacts and benefits of advanced IoT applications in fired heater operations within refineries, offering insights into efficiency improvements, predictive maintenance, safety enhancements, and sustainability.

Fired heaters are critical components in the refining process, responsible for heating crude oil to temperatures that facilitate the separation and chemical reactions necessary for producing fuels and other valuable products. Traditionally, these heaters have required significant manual oversight and have been subject to efficiency and safety challenges. However, the advent of IoT technology promises to transform this scenario by embedding intelligence into these critical systems.

One of the primary advantages of IoT in fired heaters is the substantial improvement in operational efficiency. Sensors and smart devices can continuously monitor conditions such as temperature, pressure, and flow rates in real-time. By integrating these data streams into a centralized system equipped with AI, refineries can optimize fuel consumption and heat distribution, significantly reducing energy wastage and operational costs.

For example, IoT devices can adjust burner operations dynamically based on real-time data, ensuring that heaters operate at optimal conditions, thus maximizing heat transfer efficiency and minimizing carbon emissions. Additionally, advanced analytics can predict when energy demand will peak, allowing refineries to adjust their processes accordingly.

IoT technology enhances predictive maintenance capabilities by detecting potential failures before they occur. Sensors placed on critical components of fired heaters, such as burners, tubes, and stacks, can monitor signs of wear, corrosion, or failure. This data, when processed through predictive algorithms, can forecast equipment malfunctions, allowing maintenance teams to intervene preemptively.

This proactive approach not only extends the lifespan of the equipment but also reduces downtime and maintenance costs. It significantly lowers the risk of catastrophic failures that could lead to shutdowns or hazardous situations.

The implementation of IoT in fired heaters also dramatically improves safety standards. By continuously monitoring the operating conditions and performing real-time analysis, IoT systems can instantly detect anomalies that may indicate safety risks—such as leaks or overheating—and trigger alarms or even shut down operations to prevent accidents.

Moreover, IoT can enhance the safety of personnel by minimizing their exposure to hazardous conditions, as many monitoring tasks that traditionally required manual intervention can now be automated and remotely controlled.

IoT can play a pivotal role in making fired heater operations more sustainable. By optimizing fuel usage and reducing greenhouse gas emissions, IoT technologies contribute to more environmentally friendly refining processes. Additionally, better maintenance and operational efficiency prolong the equipment's life and reduce the need for new resources and parts, further diminishing the environmental footprint.

Image title

The future of IoT in refining looks promising, with emerging technologies like 5G enhancing the capabilities of IoT solutions through faster, more reliable wireless communications. As IoT technology evolves, the integration with other digital innovations such as digital twins, augmented reality (AR), and blockchain could further transform fired heater operations.

Digital twins can create virtual replicas of fired heaters, enabling simulation and testing of changes in a virtual environment before implementing them physically. AR can assist maintenance personnel in performing complex procedures, and blockchain can secure data exchanges across the IoT network, ensuring data integrity and traceability.

The role of IoT in revolutionizing fired heater operations in refineries is becoming increasingly significant. As refineries embrace digital transformation, the potential for IoT to drive improvements in efficiency, maintenance, safety, and sustainability is immense. This evolution not only supports operational goals but also aligns with broader industry trends towards greater automation, safety, and environmental responsibility. Future advancements in IoT technology promise even greater gains, making