Introduction:

Fuel control systems play a pivotal role in maximizing the performance of API 560 fired heaters, ensuring efficient combustion and reliable operation. API 560 sets industry standards for the design, materials, and operation of fired heaters. In this article, we delve into the intricacies of fuel control systems within API 560 fired heaters, examining their crucial components, functions, and significance in achieving optimal performance and operational excellence.

Understanding Fuel Control Systems in Fired Heaters:

Fuel control systems regulate the fuel flow into the burner of a fired heater, enabling precise control over the fuel-air mixture. They are instrumental in achieving efficient combustion and maintaining desired operating conditions. These systems consist of various components that work in unison to deliver accurate fuel flow rates and ratios.

Key Components of Fired Heater Fuel Control Systems:

1. Fuel Supply System:

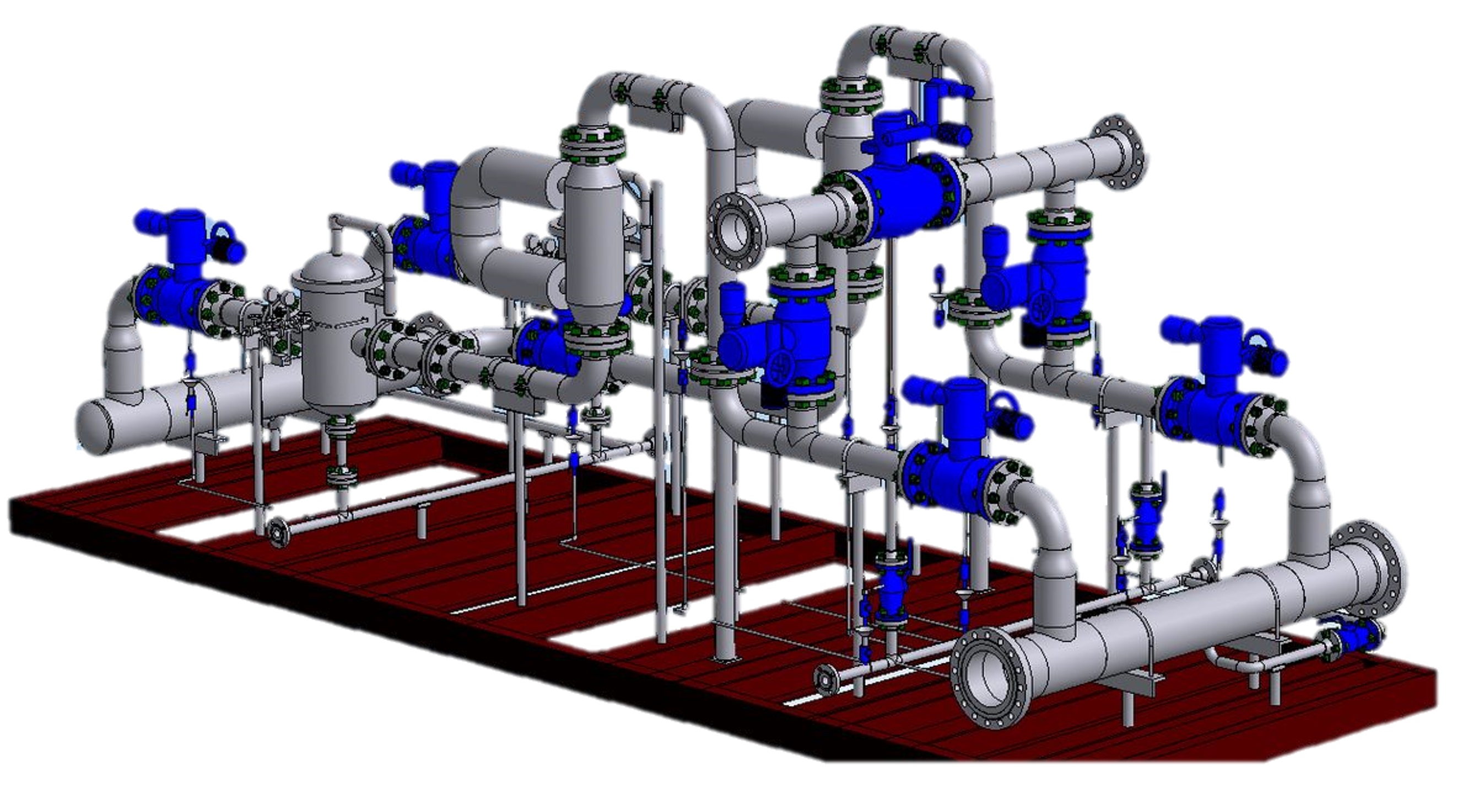

The fuel supply system ensures a consistent and clean fuel supply to the burner. It comprises storage tanks, pumps, filters, and pressure regulators, along with safety features like flame arrestors and emergency shutdown valves. These components ensure a reliable fuel source for the fired heater.

2. Fuel Flow Measurement:

Accurate measurement of fuel flow is crucial for precise control. Fuel flow meters, including orifice plates, turbine flow meters, or Coriolis flow meters, monitor and measure the fuel flow rate into the burner. The control system utilizes this data to adjust the fuel-air ratio accordingly.

3. Fuel-Air Ratio Control:

Maintaining the correct fuel-air ratio is vital for efficient combustion. Fuel control systems employ control valves, dampers, and air registers to regulate the flow rates of fuel and combustion air. These components ensure the optimal stoichiometric ratio for complete combustion, minimizing emissions and maximizing heat transfer efficiency.

4. Combustion Control System:

The fuel control system interfaces with the overall combustion control system of the fired heater. This system includes sensors, controllers, and actuators that monitor and adjust parameters such as temperature, pressure, and oxygen levels to maintain stable and efficient combustion.

Importance of Fuel Control Systems in Fired Heaters:

1. Enhanced Combustion Efficiency:

Precise control of fuel flow and fuel-air ratios results in efficient combustion within fired heaters. Accurate control minimizes excess air, reduces fuel waste, and optimizes heat transfer, leading to improved energy efficiency and reduced emissions.

2. Safety and Reliability:

Fuel control systems incorporate safety features such as flame detection and emergency shutdown capabilities to ensure safe operation. These systems help prevent fuel leaks, flameouts, and other hazardous situations, enhancing the overall reliability and operational integrity of fired heaters.

3. Compliance with Industry Standards:

API 560 provides guidelines for designing and operating fired heaters. Implementing a well-designed fuel control system that meets these standards ensures compliance, adherence to industry best practices, and meets regulatory requirements.

4. Operational Flexibility:

Sophisticated fuel control systems offer operators the ability to adjust fuel flow rates, fuel-air ratios, and other parameters to accommodate process variations. This flexibility enables optimized performance under varying operating conditions and improved process control.

Summary:

Fuel control systems are indispensable components of API 560 fired heaters, optimizing combustion efficiency, ensuring safety, and facilitating compliance with industry standards. By accurately controlling fuel flow rates and fuel-air ratios, these systems drive enhanced energy efficiency, reduced emissions, and improved overall performance.

Investing in a well-designed and well-maintained fuel control system contributes to maximizing the potential of fired heaters, resulting in improved operational excellence and process optimization.