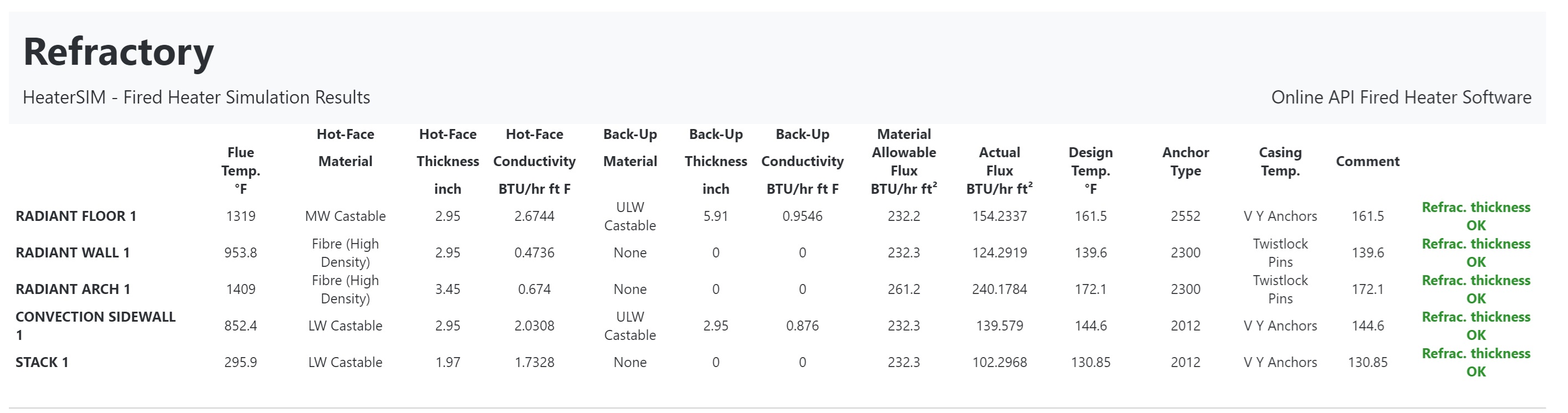

In fired heaters, refractory lining plays a critical role in protecting the metal casing from high temperatures and ensuring efficient heat transfer. This article discusses the process of calculating the required refractory thickness inside a fired heater according to the guidelines provided in API 560. It also includes relevant conductive heat transfer calculations.

Image title

API 560 sets the standards for the design of fired heaters, emphasizing the importance of refractory linings for energy efficiency and operational safety. Refractory thickness needs to be optimized to balance between heat conservation and adequate protection of the steel shell. An appropriate refractory thickness ensures the heater casing does not exceed specified temperatures, maintaining structural integrity while minimizing heat loss.

The choice of refractory material is influenced by the nature of the process and operating temperature. Common materials include:

Image title

Refractory thickness calculation hinges on the conductive heat transfer equation, which can be expressed using Fourier's law:

q = k * A * (T_hot - T_cold) / L

where:

The thermal conductivity is usually temperature-dependent and is provided by the material manufacturer.

Choose a refractory material based on process requirements and obtain its thermal conductivity data.

The equation can be rearranged to solve for the thickness:

L = k * (T_hot - T_shell) / q

Assuming:

Verify that the calculated thickness meets the requirements of API 560:

In this example, the calculated thickness of 2.4 m is excessive. Thus, the heat flux assumption must be revisited to align with practical expectations.

The thermal conductivity of refractory materials changes significantly with temperature. As temperature rises, most refractory materials exhibit an increase in conductivity, which impacts the overall heat transfer rate. This relationship is crucial when designing the refractory lining thickness to ensure accurate heat transfer calculations.

The graph below shows the variation of thermal conductivity with temperature for different refractory materials:

Image title

Inadequate refractory design or poor maintenance practices can significantly impact the efficiency and safety of a fired heater. Key concerns include:

Therefore, following API 560 requirements and implementing a rigorous maintenance schedule are essential to ensuring optimal performance and longevity of the refractory lining.

Calculating the refractory thickness in accordance with API 560 involves understanding the process parameters, selecting suitable refractory material, and applying heat transfer equations. By optimizing the refractory thickness, operators can ensure energy-efficient fired heater operations while protecting the steel shell from excessive heat.

Image title