Fired Heaters in Refinery

API (American Petroleum Institute) fired heaters play a pivotal role in the refining and petrochemical industries, providing the essential heat required for various processes. These heaters come in different configurations and designs, each tailored to specific applications and operational requirements. In this comprehensive guide, we delve into the various types of API fired heaters, highlighting their features, advantages, and typical applications.

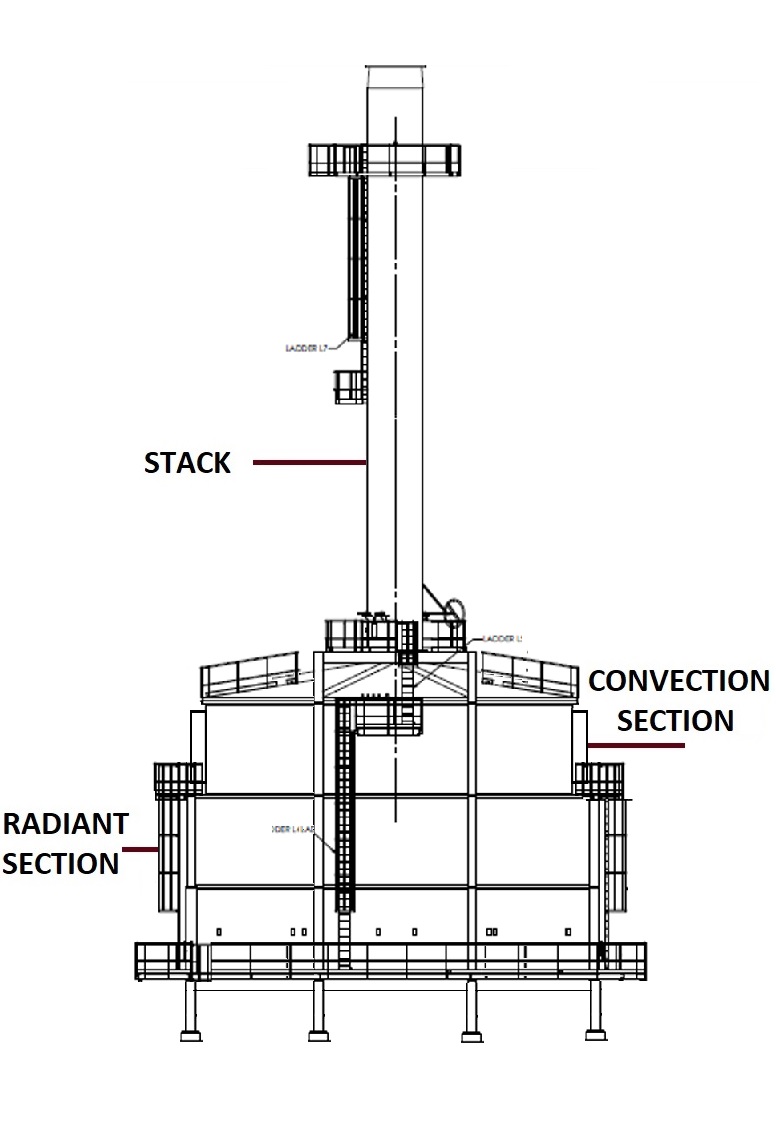

The vertical cylindrical heater is one of the most common types of API fired heaters. It features a tall, cylindrical design with the burner located at the bottom of the heater. This configuration allows for efficient heat transfer and uniform temperature distribution throughout the heater. Vertical cylindrical heaters are well-suited for applications requiring high heat transfer rates and can accommodate a wide range of process fluids and temperatures.

Vertical Cylindrical Fired Heater

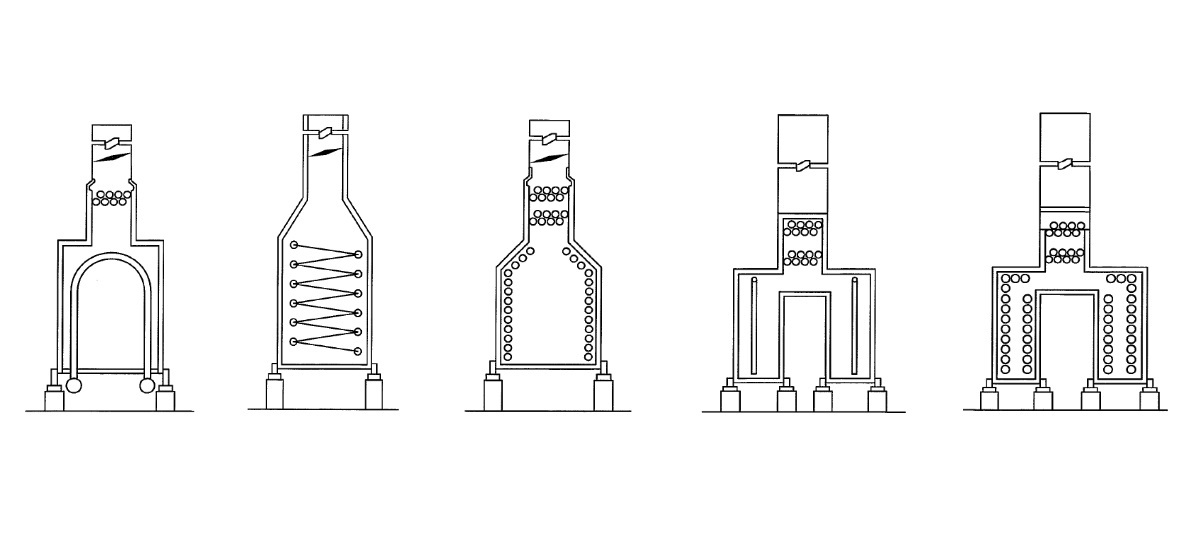

The cabin horizontal coil heater, also known as a cabin heater, features a compact design with horizontal coils housed within a cabin-like structure. This design maximizes heat transfer surface area while minimizing the overall footprint of the heater. Cabin heaters are often used in applications where space is limited, such as offshore platforms or small refineries. They offer excellent thermal efficiency and can handle high process temperatures with ease.

API 560 Cabin Fired Heater External Side view

Box heaters with vertical tubes are characterized by their box-like shape and vertical tube bundles arranged within the heater enclosure. This design allows for efficient heat transfer and easy access for maintenance and inspection. Box heaters are commonly used in applications where precise temperature control is required, such as in the production of specialty chemicals or pharmaceuticals. They offer flexibility in terms of fuel options and can accommodate various process fluids and operating conditions.

The helical coil heater features a coil-shaped heat exchanger arranged in a helical pattern within the heater enclosure. This design maximizes heat transfer surface area while minimizing pressure drop and fouling potential. Helical coil heaters are ideal for applications involving high-viscosity fluids or where the process stream contains solids or contaminants. They offer excellent thermal efficiency and can handle high flow rates and temperatures.

Typical API 560 Fired Heater Types

API fired heaters can also be classified based on the direction of the burner flame relative to the process fluid flow.

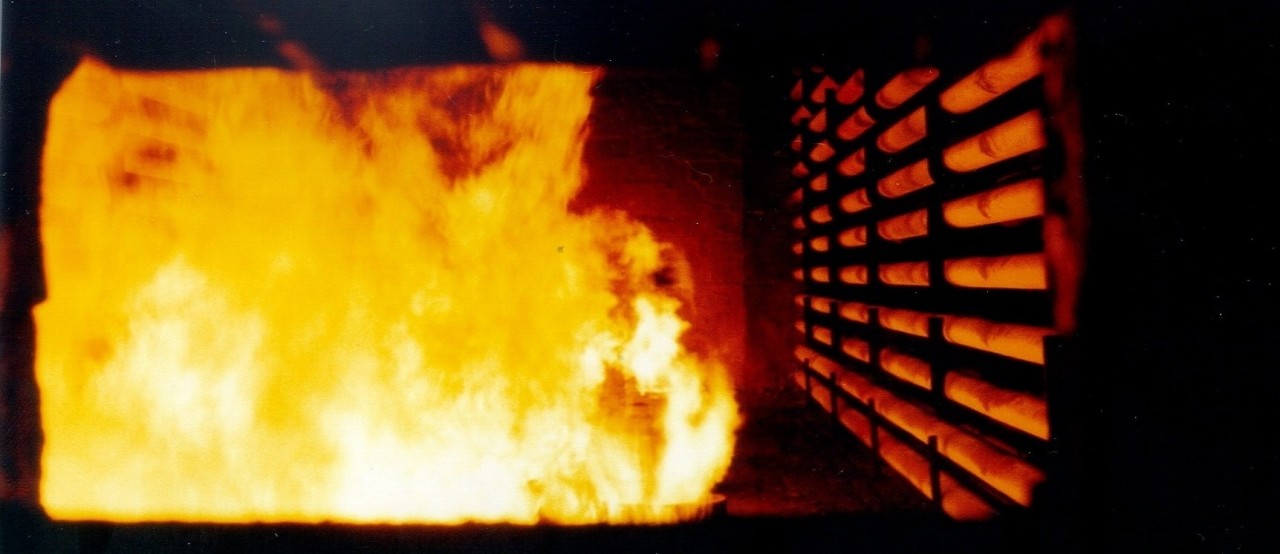

Side firing heaters have the burner located on the side of the heater, perpendicular to the process flow. This configuration allows for efficient heat transfer and uniform temperature distribution across the heater tubes.

Up firing heaters have the burner located at the bottom of the heater, directing the flame upward against the heater tubes. This design is suitable for applications requiring high heat flux and rapid heat transfer.

Down firing heaters have the burner located at the top of the heater, directing the flame downward against the heater tubes. This configuration is often used in applications where heat-sensitive materials are being processed or where space constraints limit the height of the heater.

Up Firing API Cabin Fired Heater

API fired heaters are versatile in their ability to utilize various fuels for combustion, catering to the specific requirements and availability of fuels in different regions and applications. Commonly used fuels include natural gas, propane, diesel, fuel oil, and refinery gases. Each fuel type offers unique advantages in terms of cost, availability, energy content, and environmental impact. Natural gas, for example, is often preferred for its clean-burning properties and relatively low emissions, making it suitable for applications where environmental regulations are stringent. On the other hand, fuel oil may be chosen for its higher energy content and lower cost in certain regions. The flexibility to switch between different fuel types allows operators to adapt to changing market conditions, fuel availability, and regulatory requirements while maintaining operational efficiency and cost-effectiveness.

Process Burner inside API Fired Heater

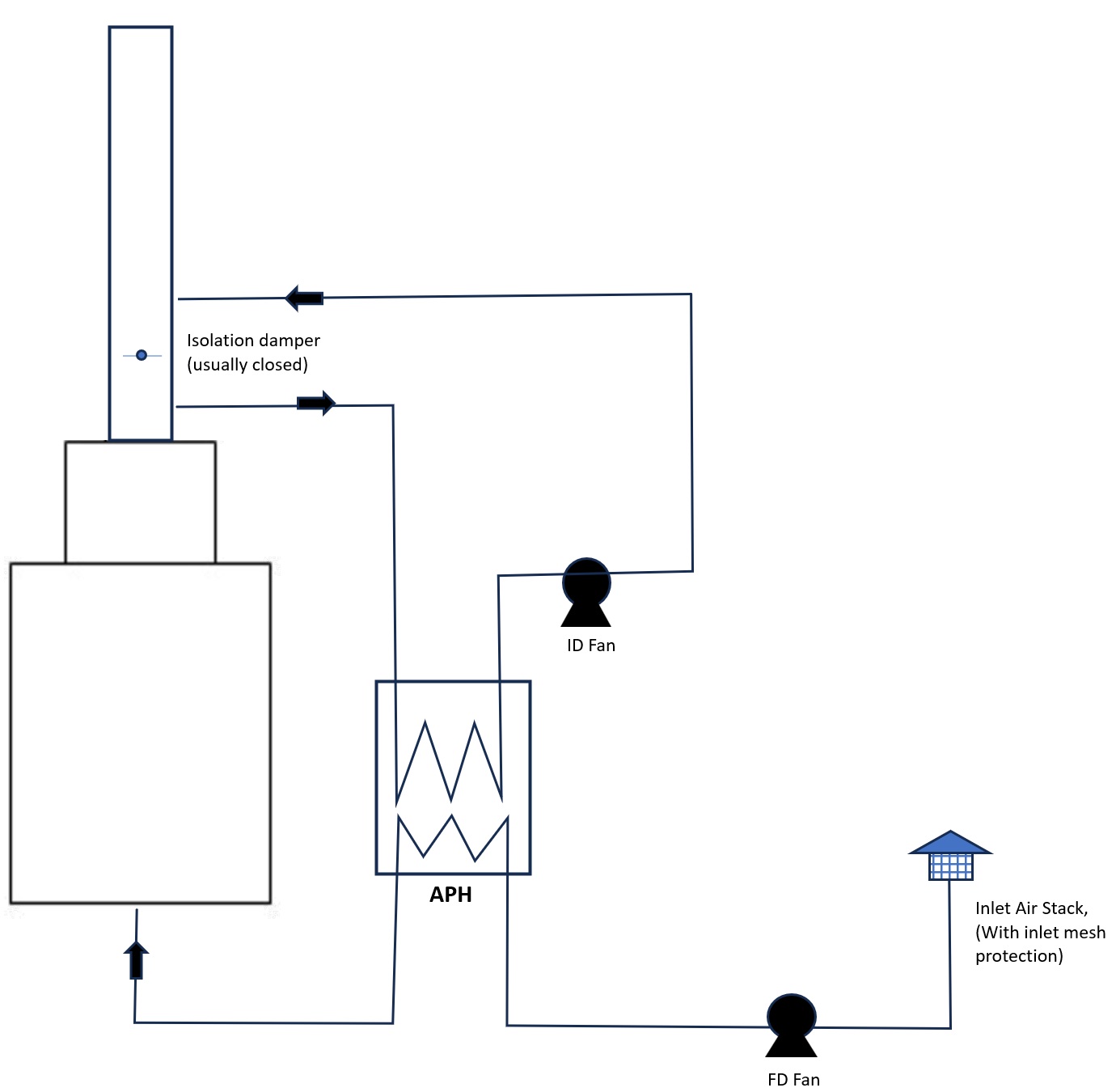

An air pre-heat system is a common feature in many API fired heaters, offering several advantages in terms of energy efficiency, fuel savings, and reduced emissions. The air pre-heat system preheats the combustion air before it enters the burner, allowing for more efficient combustion and heat transfer in the heater.

By preheating the combustion air, the system reduces the energy required to reach the desired process temperature, resulting in lower fuel consumption and operating costs. .

Additionally, preheating the combustion air helps improve combustion efficiency and reduce emissions of pollutants such as nitrogen oxides (NOx) and carbon monoxide (CO). The use of an air pre-heat system enhances the overall thermal efficiency of the fired heater, contributing to sustainable operations and regulatory compliance while optimizing energy utilization and reducing environmental impact.

Image title

In conclusion, API fired heaters come in various types and configurations, each offering unique advantages and suitability for specific applications. Whether it's the efficient heat transfer of vertical cylindrical heaters, the compact design of cabin heaters, or the versatility of box heaters with vertical tubes, there's a fired heater solution to meet every heating requirement.

Understanding the different types of API fired heaters allows engineers and operators to select the optimal heater design for their process needs, ensuring efficient operation and reliable performance.