Introduction:

Conductive heat transfer is a vital mechanism within a fired heater, significantly influencing its performance and efficiency. Fired heaters are widely utilized in various industrial processes, such as refining, petrochemicals, and power generation. Understanding the principles of conductive heat transfer within a fired heater is essential for optimizing its operation, ensuring efficiency, and maintaining safety. In this article, we delve into the intricacies of conductive heat transfer within a fired heater, exploring its characteristics, factors affecting conduction, and practical implications.

Understanding Conductive Heat Transfer in a Fired Heater:

Conductive heat transfer occurs when heat flows through solid materials due to temperature differences. In the context of a fired heater, conductive heat transfer primarily takes place within the heater's refractory lining and metal components. It enables the transfer of thermal energy from the high-temperature combustion zone to the surrounding structures and process fluids.

Characteristics of Conductive Heat Transfer within a Fired Heater:

1. Temperature Gradient:

Conductive heat transfer within a fired heater is driven by temperature differences between the hot combustion gases and the cooler surfaces. A higher temperature gradient leads to a faster rate of heat transfer through conduction.

2. Material Properties:

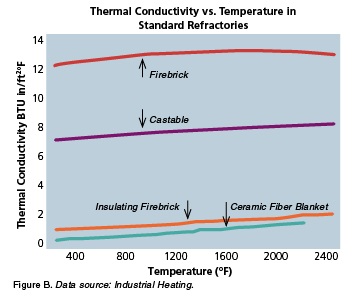

The thermal conductivity of the materials involved determines their ability to conduct heat. Different materials, such as refractory materials, metals, and insulation layers, possess varying thermal conductivities, impacting the rate of conductive heat transfer.

3. Surface Area and Thickness:

The surface area and thickness of the components play a role in conductive heat transfer. A larger surface area and thinner walls facilitate more efficient heat conduction.

Factors Affecting Conductive Heat Transfer within a Fired Heater:

Several factors influence conductive heat transfer within a fired heater, which include:

1. Material Selection:

Choosing appropriate refractory materials, metals, and insulation within the fired heater impacts conductive heat transfer. Materials with higher thermal conductivity enable faster heat conduction, while insulation materials with lower thermal conductivity reduce heat loss.

2. Design and Construction:

The design and construction of the fired heater, including the arrangement of refractory lining, insulation layers, and tube bundles, influence conductive heat transfer. Proper design considerations, such as optimal spacing and insulation placement, ensure efficient heat transfer, preventing thermal inefficiencies and equipment failure.

3. Temperature Gradients:

Temperature differentials across the refractory lining, metal components, and other structures affect conductive heat transfer. Monitoring and controlling temperature gradients are essential to maintain safe and efficient operation.

Practical Implications within a Fired Heater:

1. Enhanced Efficiency and Performance:

Understanding conductive heat transfer within a fired heater is crucial for optimizing its efficiency and performance. Proper material selection, insulation, and design considerations minimize heat loss, improve temperature uniformity, and enhance overall heater efficiency.

2. Thermal Stress and Structural Integrity:

Conductive heat transfer can subject the components within a fired heater to thermal stress and strain. Adequate design, material selection, and insulation help mitigate thermal stresses, ensuring the structural integrity of the heater and extending its operational lifespan.

3. Safety Considerations:

Managing conductive heat transfer is vital for maintaining safe operating conditions within a fired heater. Monitoring temperature differentials, inspecting refractory integrity, and ensuring effective insulation minimize the risk of equipment failure, fires, and accidents.

Summary

Conductive heat transfer plays a crucial role within a fired heater, influencing heat distribution, efficiency, and safety in industrial processes. Understanding the characteristics and factors affecting conductive heat transfer allows for optimal design, material selection, and operational practices.

By optimizing conductive heat transfer within a fired heater, industries can improve energy efficiency, enhance performance, extend equipment lifespan, and ensure safe and reliable operations.