Introduction:

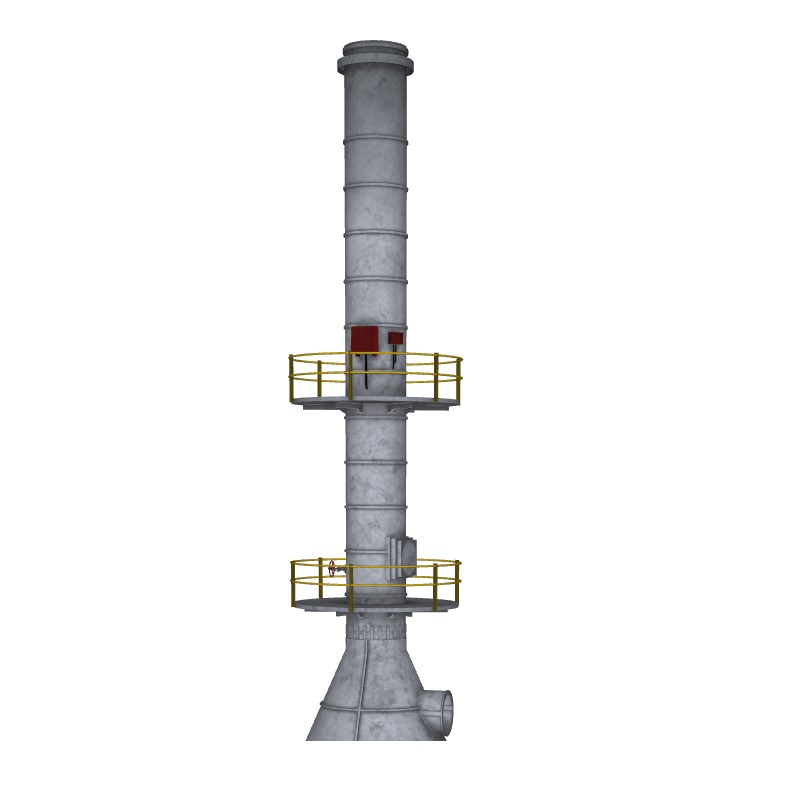

The Stack Chimney Effect is a phenomenon that occurs in Fired Heaters, where the stack or chimney height influences the natural draft and the efficiency of combustion. Understanding this effect is crucial for optimizing Fired Heater performance and minimizing energy losses. This article explores the Stack Chimney Effect, its impact on draft, and the role of HeaterSIM in analysing and optimizing stack design for optimal performance.

1. The Stack Chimney Effect:

The Stack Chimney Effect occurs due to the difference in air density between the ambient air and the flue gas inside the stack. This density difference generates a pressure difference, known as draft, which promotes the flow of flue gas from the Fired Heater to the atmosphere. A well-designed stack chimney helps ensure efficient combustion and prevent the backflow of flue gas into the furnace.

2. Calculation of Draft Pressure:

The draft pressure in a stack chimney can be calculated using the following equation:

Draft Pressure = (ρ × g × h) / A

Where:

ρ = Average density of flue gas (kg/m³)

g = Acceleration due to gravity (9.81 m/s²)

h = Height of the stack chimney (m)

A = Cross-sectional area of the stack chimney (m²)

The draft pressure is influenced by the average density of flue gas, stack height, and cross-sectional area. Higher stack heights and larger cross-sectional areas typically result in increased draft pressure, facilitating better combustion efficiency in Fired Heaters.

3. Optimizing Stack Chimney Design:

HeaterSIM software plays a vital role in analysing and optimizing stack chimney design for Fired Heaters. With HeaterSIM, operators can simulate various stack configurations, calculate draft pressures, and assess the impact on combustion efficiency. By incorporating advanced computational fluid dynamics (CFD) capabilities, HeaterSIM enables visualization of flow patterns, identification of areas of recirculation or pressure drop, and optimization of stack dimensions.

4. Factors Affecting the Stack Chimney Effect:

Several factors influence the Stack Chimney Effect in Fired Heaters, including:

- Flue Gas Temperature: Higher flue gas temperatures result in lower density, reducing the draft pressure. Optimizing the temperature through efficient heat recovery systems is crucial.

- Stack Diameter and Height: Increasing the stack diameter and height increases the draft pressure and enhances the natural draft effect, improving combustion efficiency. However, practical considerations and local regulations must be taken into account.

- Flue Gas Flow Rate: The flow rate of flue gas is influenced by the firing rate and the fuel properties. Accurate measurement and control of flue gas flow rate aid in optimizing the stack chimney design.

- Wind Conditions: External factors such as wind speed and direction impact the Stack Chimney Effect. Proper stack design considers wind effects to ensure the desired draft pressure is maintained.

Summary:

Understanding and optimizing the Stack Chimney Effect is essential for maximizing combustion efficiency and minimizing energy losses in Fired Heaters. By considering factors such as stack height, diameter, flue gas temperature, and flow rate, operators can design an efficient stack chimney system.

HeaterSIM software provides valuable tools for analysing and optimizing stack design through accurate calculation of draft pressures, visualization of flow patterns, and identification of optimization opportunities. By leveraging HeaterSIM, operators can achieve optimal stack chimney performance and enhance the overall efficiency of Fired Heaters.