Refractory Insulation of Fired Heaters

Insulation for Fired Heaters and Furnaces

Types of Insulation used inside Fired Heaters and Furnaces

The internal walls of furnaces and fired heaters are insulated with refractory lining, helping to conserve heat loss and maintain the internal temperature inside the heater. In addition, the external casing of the heater needs to be cool enough for operating staff to access safely.

API 560 Refractory Design Requirements

API 560 Standard has specific requirements to be achieved for the external casing. These requirements are as follows:

- 90 deg C (195 deg F) at the floor

- 82 deg C (180 deg F) on the walls

- 0 m/s (0 mph) wind speed

- 27 deg C (80 deg F) ambient air temperature

Note: our simulation technology includes for API 560 design requirements as default, however, you have the freedom to adjust the design requirements as you wish.

Most common refractory materials for Fired Heaters

In recent years, the most common type of refractory used inside Fired Heaters are as follows:

- Castable Refractory

- Ceramic Fibre Insulation

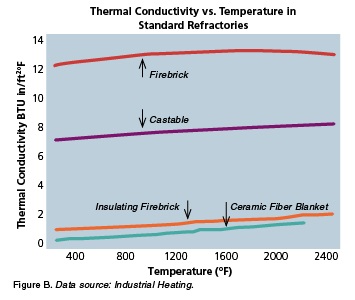

Conductivity of Various Refractory Insulation Materials

Castable

Castable refractory has traditionally been used in fired heaters for over 40 years. The process of installing this refractory involves mixing powder with water, applying this ‘wet-mix’ on to the required internal surfaces of the fired heater, which is then followed by an extensive drying out procedure.

Traditionally, this refractory has been applied throughout all areas of the fired heater. However, in recent years, fired heaters utilise ceramic fibre insulation in the radiant section and castable refractory applied elsewhere.

Ceramic Fibre

Fired heaters have increasingly utilised Ceramic Fibre insulation over the last 20 years. Fibre has a lower weight than Castable refractory and is much simpler to install, which presents significant advantages when manufacturing the heater

Although most commonly used in Radiant sections only, installation of fibre throughout all areas has become a more frequent occurrence in recent fired heater projects. In some instances, a stainless steel mesh or thin plate is used to further secure the fibre position (particularly where high flue gas velocities are expected).

If you need any assistance with your fired heater project, please feel free to get in touch