Introduction:

Convective heat transfer is a significant mode of heat transfer that plays a crucial role in numerous industrial processes, including energy production and heat exchangers. When hot flue gas flows over a tube bundle, convective heat transfer becomes a critical factor in transferring thermal energy from the flue gas to the tubes.

This article delves into the intricacies of convective heat transfer in this scenario, exploring its characteristics, influencing factors, and practical implications.

Understanding Convective Heat Transfer:

Convective heat transfer involves the transfer of heat energy through the motion of a fluid, which can be a gas or a liquid. The heat transfer occurs due to the combined effect of conduction and fluid motion, known as convection. In the context of hot flue gas flowing over a tube bundle, convective heat transfer allows the thermal energy of the flue gas to be transferred to the tubes, facilitating efficient heat exchange.

Characteristics of Convective Heat Transfer:

1. Fluid Flow Patterns:

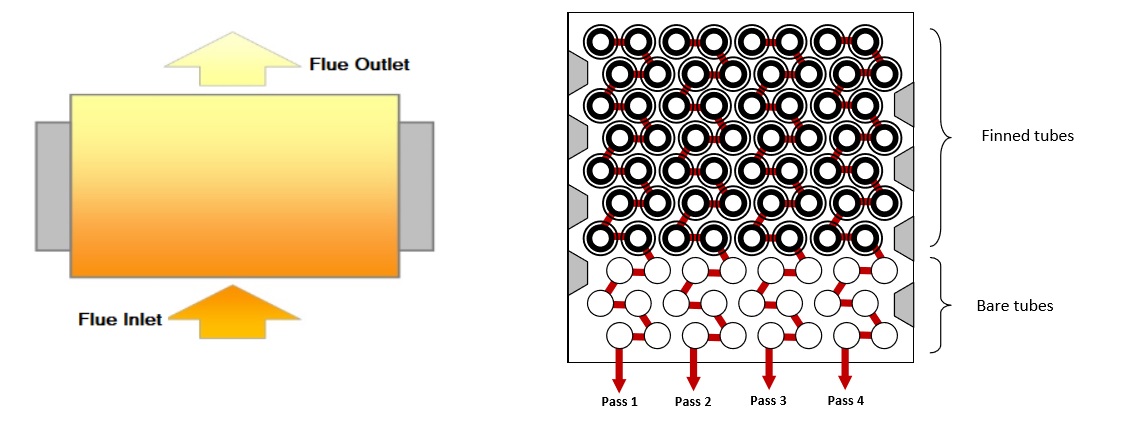

The flow patterns of the hot flue gas over the tube bundle significantly influence convective heat transfer. Various flow patterns can occur, including laminar flow, turbulent flow, or a combination of both. Turbulent flow, characterized by chaotic and irregular fluid motion, generally enhances convective heat transfer due to increased mixing and turbulence.

2. Heat Transfer Coefficient:

The convective heat transfer coefficient represents the efficiency of heat transfer between the flue gas and the tube surfaces. It depends on factors such as fluid properties, flow velocity, temperature gradients, and surface characteristics. A higher convective heat transfer coefficient indicates more efficient heat transfer.

3. Boundary Layers:

Boundary layers form near the tube surfaces as the flue gas flows over them. These layers consist of fluid in close proximity to the tubes where heat transfer occurs primarily through conduction. The thickness of the boundary layer influences convective heat transfer, with thinner boundary layers generally leading to more efficient heat transfer.

Influencing Factors:

Several factors affect convective heat transfer when hot flue gas flows over a tube bundle:

1. Fluid Properties:

The properties of the flue gas, including density, viscosity, and specific heat, impact convective heat transfer. These properties determine the fluid's ability to absorb and transport heat energy.

2. Flow Velocity:

The velocity of the flue gas flow plays a significant role in convective heat transfer. Higher flow velocities can enhance convective heat transfer by increasing the fluid's contact with the tube surfaces and promoting turbulence.

3. Temperature Difference:

The temperature difference between the flue gas and the tube surfaces drives the convective heat transfer. A larger temperature difference results in a higher rate of heat transfer.

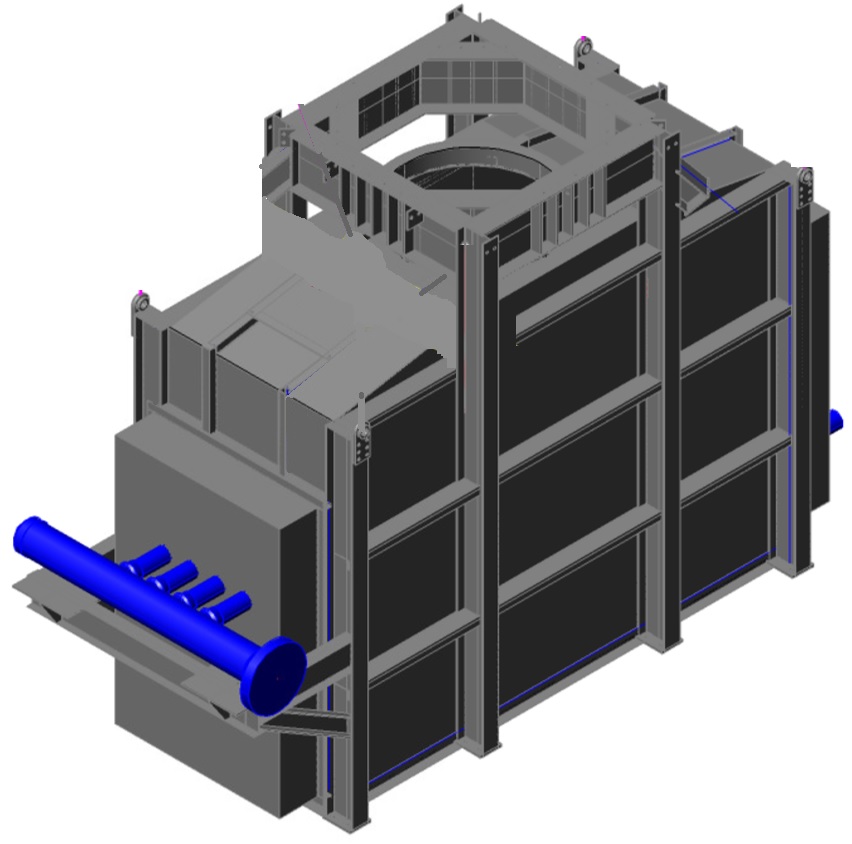

4. Tube Bundle Configuration:

The arrangement and geometry of the tube bundle affect convective heat transfer. Factors such as tube diameter, spacing, and orientation influence the flow patterns and heat transfer characteristics.

Practical Implications:

1. Energy Recovery:

Convective heat transfer in the context of flue gas and tube bundles is crucial for energy recovery. Heat exchangers utilize this heat transfer process to recover thermal energy from the flue gas and transfer it to a secondary fluid, such as water or air, for various applications, including heating and power generation.

2. Boiler Efficiency:

Efficient convective heat transfer is essential for optimizing boiler performance. Proper design and maintenance of heat exchanger surfaces and consideration of factors such as flow velocity and temperature difference can improve boiler efficiency and reduce energy consumption.

3. Industrial Applications:

Convective heat transfer involving hot flue gas and tube bundles is relevant in various industrial processes, such as waste heat recovery, industrial drying, and thermal processing. Understanding and optimizing convective heat transfer contribute to enhanced process efficiency, reduced energy costs, and improved product quality.

Summary

Convective heat transfer in the context of hot flue gas flowing over a tube bundle is a crucial mechanism for efficient heat exchange in numerous industrial processes. Understanding the characteristics and influencing factors of convective heat transfer allows for the design of effective heat exchangers, enhanced energy recovery, and improved process efficiency.

By harnessing the principles of convective heat transfer, industries can maximize thermal energy utilization, reduce environmental impacts, and drive sustainable practices.