We use cookies to improve user experience on our website. By using our website, you consent to the use of these cookies.

We use cookies to improve user experience on our website. By using our website, you consent to the use of these cookies.

Maintaining a stable flame is essential to ensuring overall heater safety, reliability and environmental emission impact. Unstable flames can indicate incomplete fuel combustion, which can lead to an accumulation of an explosive atmosphere within the heater. Of course, this explosive atmosphere can have catastrophic consequences, threatening the lives of site personnel and huge financial impact to the operating company.

In some cases, unstable flames may make contact with the tubes directly. This may lead to the overheating of the tubes and increasing the likelihood of their eventual failure, which can also lead to devastating consequences.

Ultimately, unstable flames are the result of unsteady combustion conditions whereby either the fuel or air supply is disrupted in some way. There are a number of ways in which the fuel and/or combustion air supply may be disrupted, which include:

- Blockage or damage in fuel tips at the burner

- Disruption or blockage in the combustion air duct

- Fouling or blockage in fuel supply pipeline

- Faulty control valves

- Fault within the combustion control logic

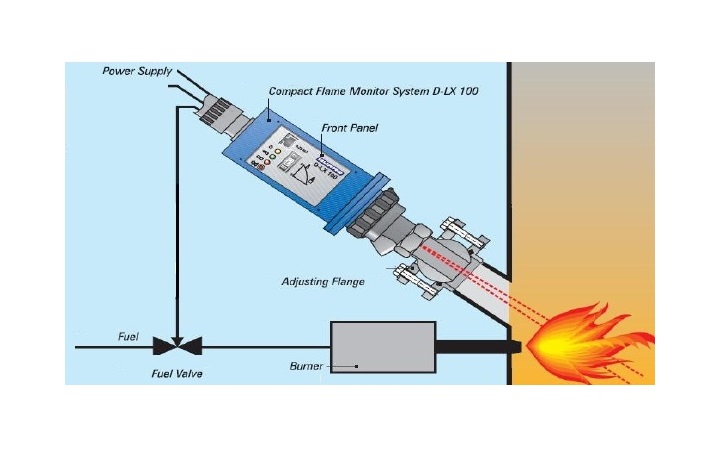

Modern Fired Heaters and Furnaces built today will likely include flame loss detection logic within the BMS (Burner Management System). Typically, the flames within the heater will be continually monitored for each burner using a UV scanner. If the scanner detects flame loss, the BMS will automatically shutdown the fuel supply to the particular burner.

This system is great in the event of flame loss (i.e. whereby the flame becomes unstable to the point of loss), but actually doesn’t protect whereby the flame becomes unstable but doesn’t exstinguish. Detection of this situation is harder to detect, but some instruments may tell us that something is not quite right with the combustion. For example, the combustion instability may be reflected in the following items:

- CO analyser

- O2 Analyser

- NOx Analyser

Therefore, careful monitoring of these analysers can indicate whether there is an issue with combustion. Ideally, this monitoring should be done alongside ‘good old fashioned’ routine observation of the flame where possible, to ensure the shape, colour and vigour of the flame remains suitable.

If you need any assistance with your heater project, please feel free to get in touch

COVID-19 secure

something wrong

something wrong

Thank you for getting in touch.

We use cookies and other technologies to improve the browsing experience on our website.

By using our website, you consent to the use cookie technologies.