Our Fired Heater Digital Technology & Solutions offer unparalleled precision, efficiency, and safety for modern industrial operations. Designed to optimize performance while reducing emissions, our technology leverages real-time data and predictive analytics through a secure cloud platform, enabling remote monitoring and proactive adjustments. With advanced automation and cloud connectivity, our solutions ensure maximum uptime, streamlined operations, and enhanced reliability, helping you achieve operational excellence with ease and confidence

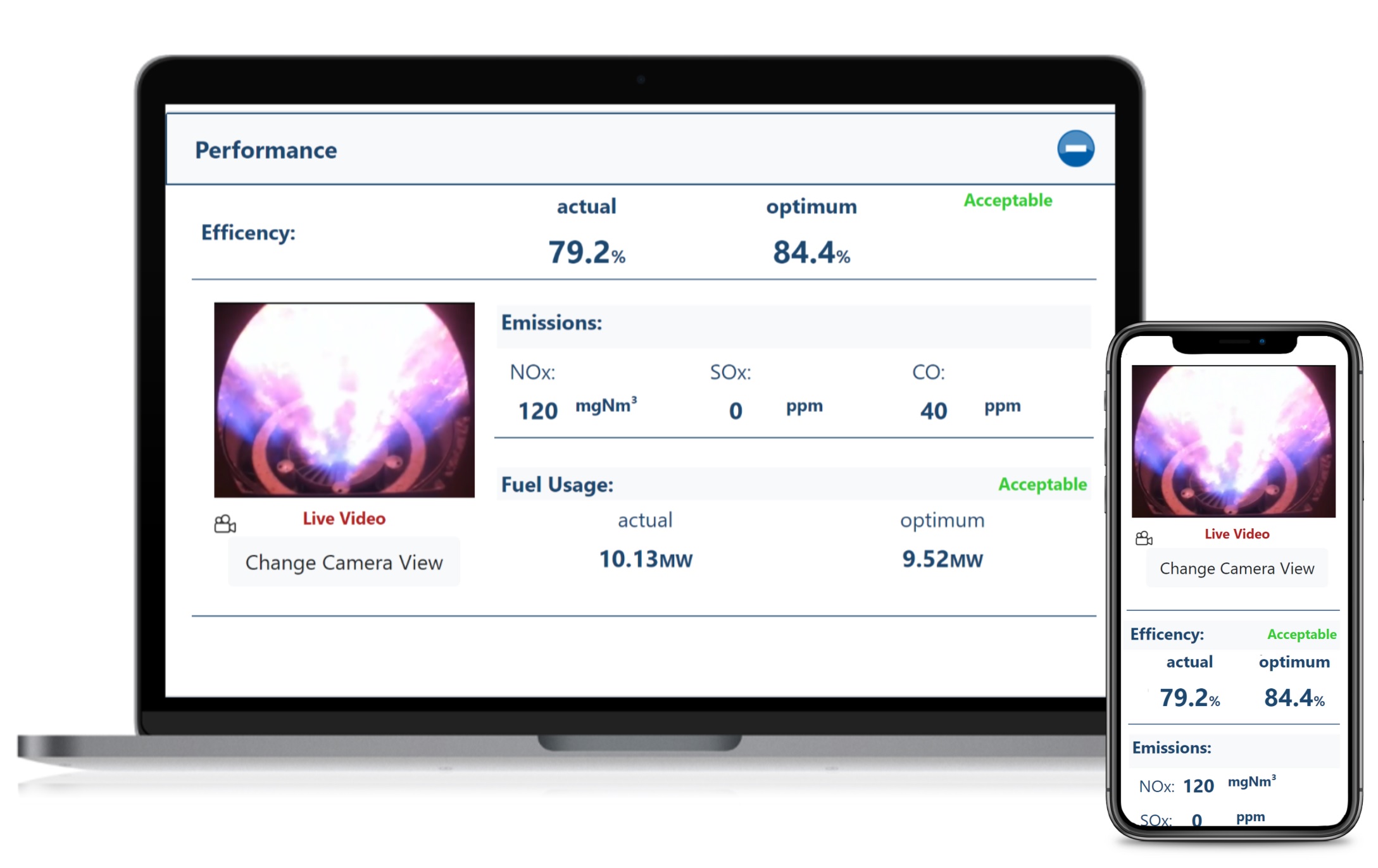

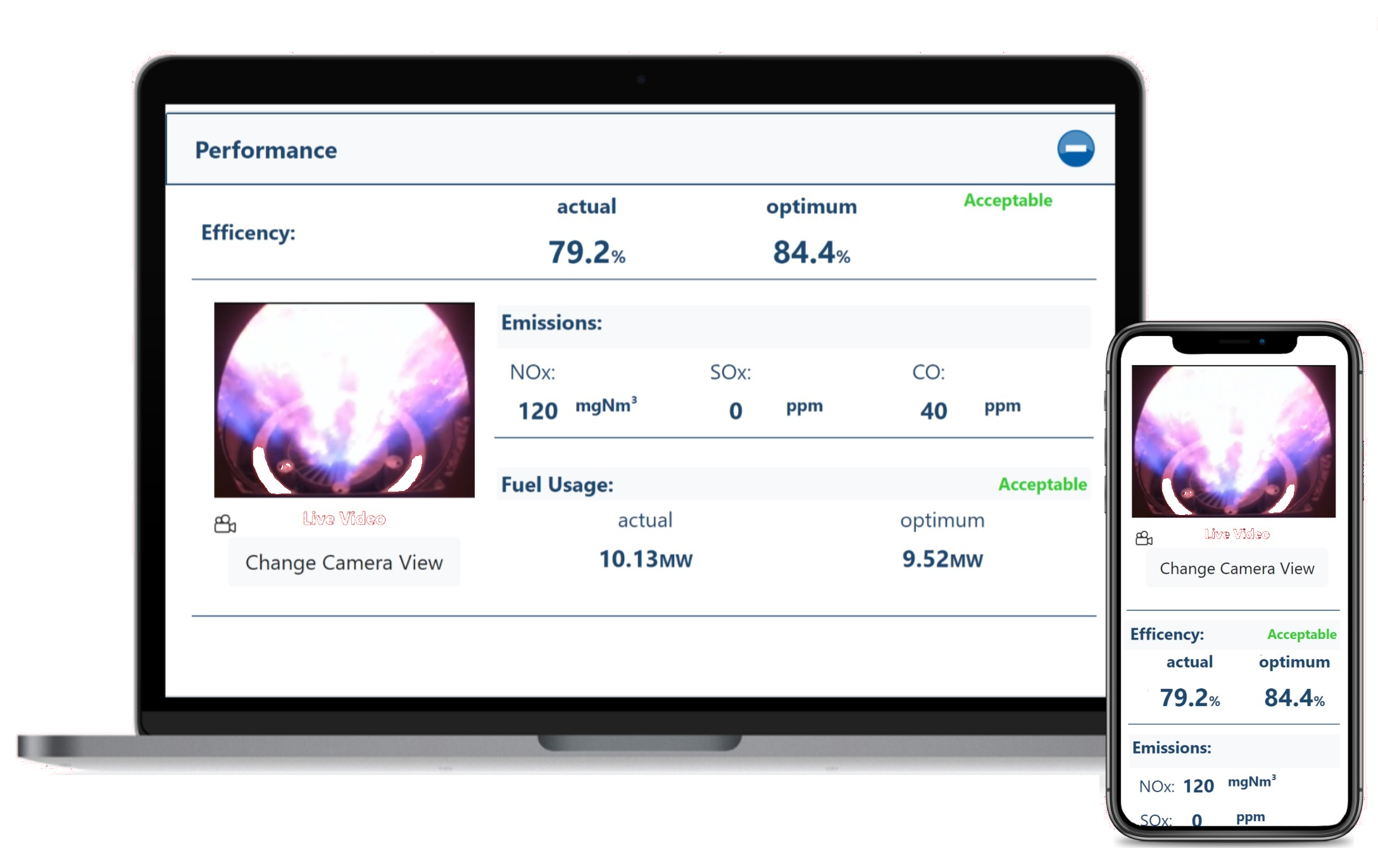

Experience the future of fired heater management with our advanced digital twin technology for API Fired Heaters. This innovative solution creates a real-time virtual replica of your fired heater, allowing you to monitor, analyze, and optimize performance from anywhere. By leveraging data-driven insights and predictive analytics, our digital twin technology helps you anticipate maintenance needs, reduce unplanned downtime, and extend equipment lifespan. It enables proactive decision-making, ensuring safety and efficiency while maximizing operational reliability. Transform how you manage your fired heaters with our digital twin technology and stay one step ahead in operational excellence

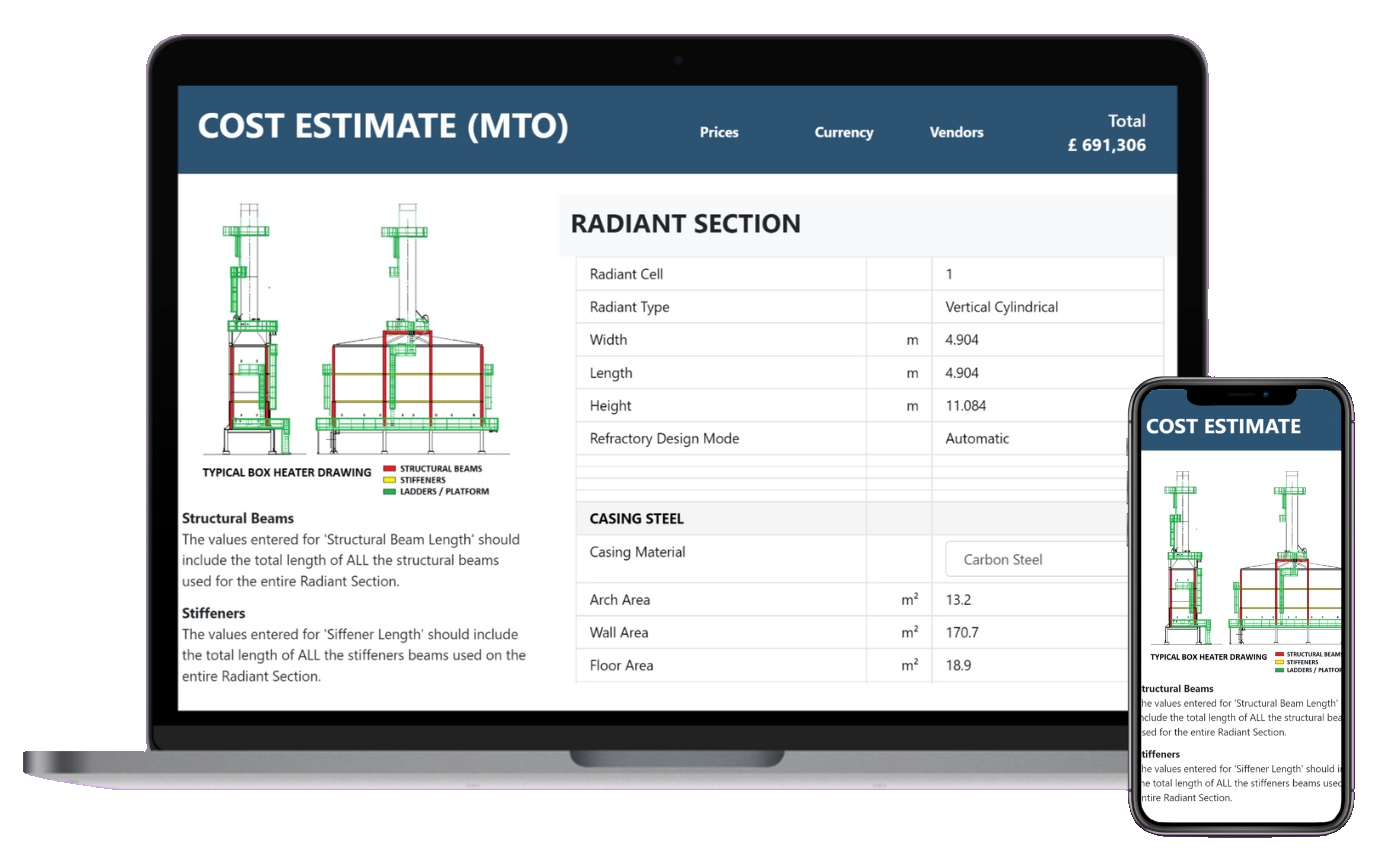

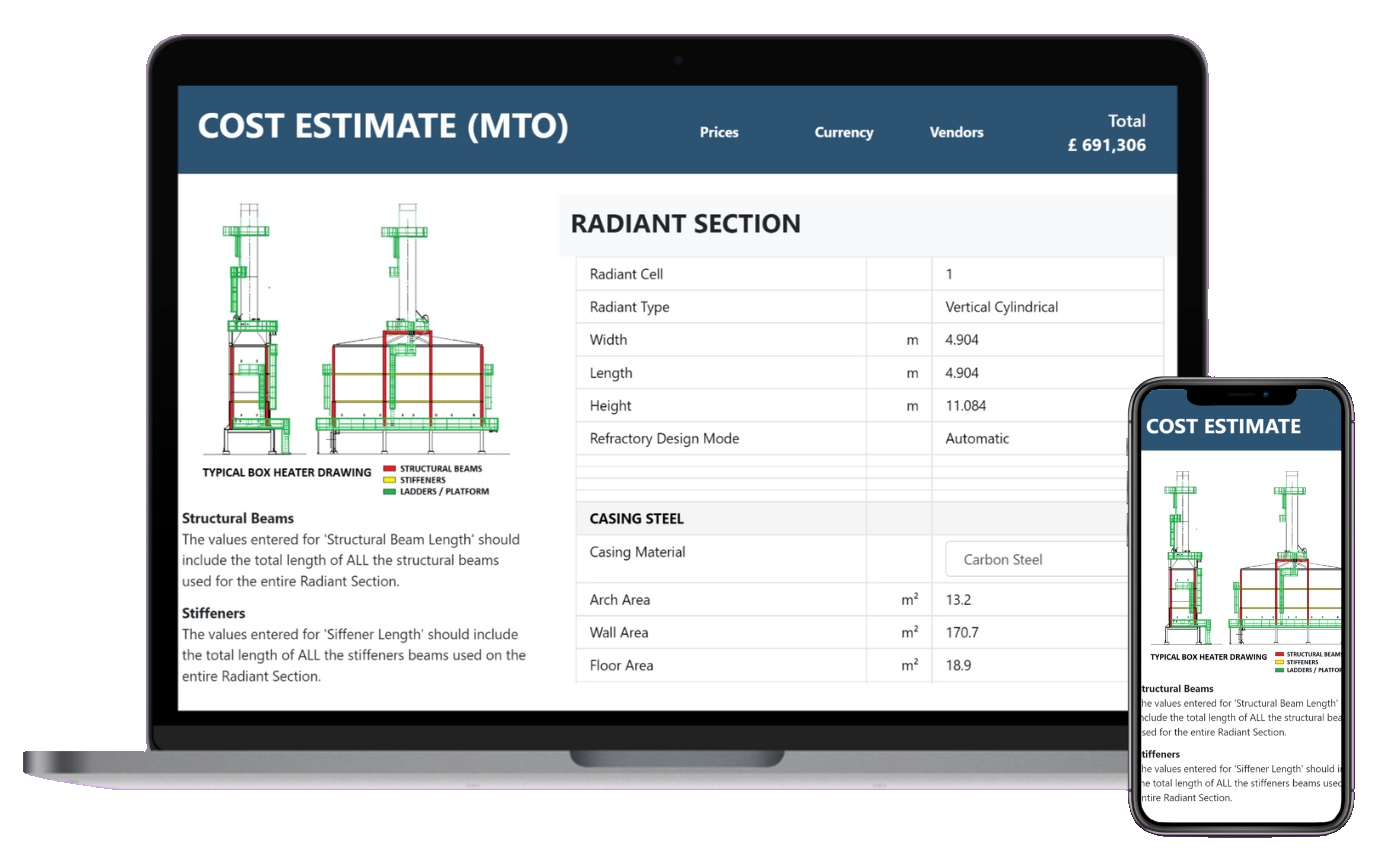

Our software’s detailed cost estimation feature for Fired Heaters is designed to provide a comprehensive, accurate breakdown that simplifies project budgeting and enhances bid precision. This powerful tool considers every critical component—including tubes, fittings, welding, steel columns, refractory materials, burners, and instruments—to deliver a fully itemized estimate tailored to your specifications. By automating the complex costing process, it saves valuable time while ensuring no detail is overlooked. With this feature, you can confidently present thorough, transparent cost assessments that improve bid competitiveness and streamline project planning from the start.